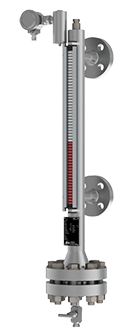

Description

Bypass level indicators form an integral part of the pressure vessel. Via two process connections a standpipe ( bypass ) is mounted

to the side of a tank or vessel. Due to the direct connection the filling level in the bypass will always correspond

exactly to the filling level in the vessel ( communicating pipes ).

In the bypassing pipe a cylindrical float with a built-in magnetic system is contained. The concentrated magnetic field of the permanent magnet

corresponds exactly to the filling level of the liquid in the bypass. In a contactless way the magnetic field transmits itself through

the wall of the standpipe onto externally mounted displaying, recording and switching elements.